LC400 Lift Controller

The LC400 lift control unit has the ability to control the floor access of one lift cab/elevator and supports access to up four floors (out of the box) or up to 128 floors via I/O expansion boards.

Using the LC400 Lift Controller and constituent devices the AC2000 system can provide access control to specific lift floors within a building. From a cardholders perspective it is as simple as them entering a lift cab, presenting their card to a CEM access control reader, which in conjunction with the LC400 Lift Controller carries out access checks on the AC2000 database to determine which floors the cardholder is allowed access to. This information is then presented to the lift via a Lift Control Interface series of relays, used to enable the floor selection buttons in the cab.

The cardholder can then select an enabled floor and the lift cab will proceed as normal. Depending on the lift specification the LC400 Lift Controller can also record which floor selection the cardholder requested, allowing reports to be generated at a later date. The LC400 Lift Controller provides full 10/100 Base-T Ethernet connectivity for host connection using secure TLS v1.2 transport, allowing the administrators to use browser based user interface to remotely monitor the controller at any time.

Interested?

Onboard database

The LC400 Lift Controller supports its own database of up to 250,000 card records. The records include card numbers, access level and time zone details. The database allows the controller to validate card requests from the lift cab readers even when communications with the AC2000 system have been lost. Card transactions, floor selections and alarms are stored until communications are restored at which point they are uploaded to AC2000 ensuring no access control event is ever lost.

Offline operation - lift control interface

Connection between the LC400 Lift Controller and the lift cabin’s floor selection panel is accomplished via a Lift Control Interface (LCI) containing one or more sets of input/output modules. Various LCI options are available to support up to 128 floors. Output modules are used to signal to the lift which floor selection buttons to enable. Each output module provides 16 dry contacts, with one being used per available lift floor. Input modules provide 16 analog inputs. Inputs are included to provide a mechanism for the lift to signal back when floor selection has been made and which floor was selected. Again one input is used per monitored lift floor.

It is recommended to contact a CEM sales representative to discuss your specific requirements before ordering any Lift Control Modules.

The interface between the system and the lift hardware depends considerably upon the lift manufacturer, model, and the specific requirements on site. It is important that the integrator communicates closely with CEM Systems prior to placing an order to determine the precise installation requirements, which may vary greatly between installations.

Intelligent features for installation and maintenance

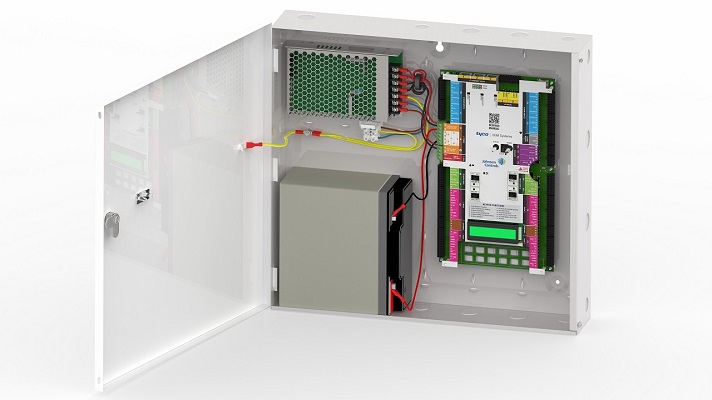

The LC400 is designed for ease of installation. The installer simply enters the unit’s unique ID and device configuration on the server, sets the networking configuration on the panel, and connects to the network. The backlit LCD, twelve character keypad, intuitive overlay, LED status indicators, and web pages on the LC400 help to reduce time of installing and troubleshooting. External LED indicators provide visual confirmation of power and connectivity without the need of opening the enclosure, while the backlit LCD display on the LC400 board provides easy to read status and troubleshooting information.

The on-board keypad allows configuration and troubleshooting to be handled directly on the board for ease of installation and maintenance. Spare network points allow for local access to diagnostic web pages. The installer led design of the LC400 enclosure also includes a removable enclosure door for ease of access and an increased number of punchouts in the enclosure for improved cable management.

Web dashboard

The LC400 dashboard can assist with local and remote troubleshooting, monitoring and configuration of the LC400. The dashboard provides users with visual indicators and details on power supply status, input states, output status, network status, and database status.

The dashboard also allows users connected to the LC400 network the ability to remotely configure network settings and current limits for outputs (read heads and auxiliary outputs).

Features

- Intelligent embedded network device for control of a lift cab with the CEM AC2000 system

- Supports access to four floors or up to 128 floors via I/O expansion boards

- 128MB flash for database

- Storage capacity for up to 250,000 card records

- Full TCP/IP based diagnostics/monitoring available via web browser

- Full Cabinet Tamper, AC Power Fail, Low battery (when fitted)

- Overlay wiring guide

- Onboard LEDs and LCD display provides status information

- Twelve character touchpad